The second thing you should notice is that from scarf to scarf, the plies look the same. You can either pay particularly close attention to this or do what I do and cut the planks a few inches wider than you will need. typically this gets lost a n inch or so from the ends as that is where the plane enters and exits the work area. First, the lines will be straight across the planks with no waves in the ply lines.

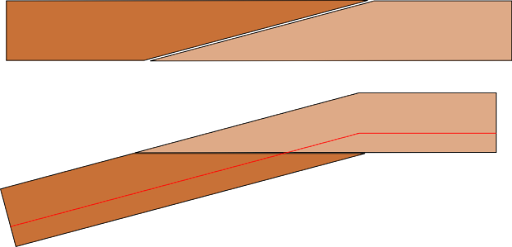

If your scarf is true you will see two things. As you scarf the planks you will see the lines of the plies showing distinctly. The interesting thing about working with marine plywood is that it gives you a built in gauge. Remember that the trick to this is when you are don that all the angles should be the same. I use the power plane to get me close (very close), just be sure that as you get close you lower the cutting depth of the plane so that you are sure you don't over do it. I am not saying it won't work, I am simple saying why? A cheap power plane these days is about the same price as a good hand plane and trust me when I tell you that the power plane will take that wood down far faster than the trusty Stanley If that makes me a hack, then I say plug in and hack away! It makes me chuckle when I see a book or another article showing someone with their faithful Stanley plane working their scarf joint. The only thing to watch for here is to make sure that the ends of you plywood are flat to the table or each other and not lifting up which will distort your scarf joint.Īs you can see from the picture I am far from a purist when it comes to tools. I use a table made to fit on top of two saw horses the same height as my work bench and I clamp or screw my panels together. Be sure it is good and steady as the last thing you want is the planks moving about as you are trying to make your scarf. Start by finding or building a good solid work table that will support the width and breadth of your planks. Your boat plans will undoubtedly tell you the type of planks you will need. This will not be enough to cover the bottom of the entire boat but stacking more than 3 sheets of 3/4" plywood makes the reach simply too far for me. You can see that we have 3 sheets stacked and when this side is done we will be flipping them over and scarfing them on the other end. The panels shown here are 5' wide by 3/4" thick, so the scarf will be 6" deep and will be used for the bottom of a large power dory. In these pictures we show stacking the panels, you will have to try both to see what works for you.

It takes me less time to scarf 3 panels individually than it does for me to stack 3 panels and scarf them all at one time. In theory this is true and I have done it many times, however that said, I will tell you that I personally have better results scarfing one ply at a time. Now there are those that would tell you that stacking multiple layers of plywood and setting them back the distance of the scarf is an easy way to scarf more than one panel at a time. The reason for this is because of the quality of the interior plies of wood on say marine grade plywood versus the home building stuff. In fact if you can scarf cheap plywood then the good stuff is a snap. Practicing on inexpensive lumber is a good way to shake out the doubts. The concept is the same for dimensional lumber, however there are simpler methods for cutting scarfs in dimensional lumber than there are for plywood. For this article we will focus on plywood scarfing. The run can be as much as 12 times the rise and your boat plans may specify the ratio they want you to use. That is to say that if you are working with 3/4" plywood, you want to have a scarf which is 6" deep. It is a simple matter of of cutting a ramp on the wood which has a run of 8 times the rise. The concept of a scarf joint isn't complicated. the trick to getting past the anxiety of doing this is to simple get out the tools and do one. Given the right tools, this is a simple job to do. If your boat plans call for a scarf joint, don't panic.

0 kommentar(er)

0 kommentar(er)